Quality Control in PU Foam Machinery Operations

Polyurethane (PU) foam is a versatile material widely used in industries such as automotive, furniture, construction, refrigeration, and packaging. The quality of the final foam product is heavily dependent on the performance and precision of the PU foam machinery used in its production. Implementing effective quality control measures throughout the foam manufacturing process ensures consistent product performance, reduces material waste, and enhances operational efficiency.

Quality control in PU foam machinery operations involves monitoring chemical ratios, mixing quality, machine parameters, and production conditions to maintain high standards. Reputable PU Foam Machinery manufacturers incorporate features that support quality assurance, such as automated metering systems, digital monitoring, and sensors. These features enable operators to detect deviations early and ensure that each batch of foam meets specified requirements for density, elasticity, and cell structure.

Table of Contents

ToggleImportance of Quality Control

Maintaining strict quality control is essential for several reasons:

-

Consistent Foam Properties: Variations in chemical ratios or mixing can lead to uneven density, poor elasticity, or weak structural integrity. Quality control ensures uniformity across production batches.

-

Operational Efficiency: Monitoring machinery performance helps prevent downtime and reduces material waste caused by defective foam.

-

Safety Compliance: PU foam production involves reactive chemicals under pressure. Quality control measures help prevent malfunctions that could pose safety hazards.

-

Customer Satisfaction: High-quality foam meets client specifications and industry standards, strengthening trust and long-term business relationships.

Without robust quality control, foam production can result in defects that affect product performance and increase operational costs.

Key Quality Control Measures in PU Foam Machinery

Chemical Ratio Accuracy

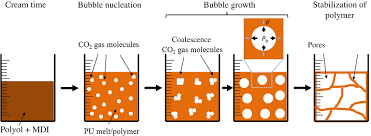

One of the most critical aspects of quality control is maintaining accurate ratios of polyol and isocyanate. Automated PU foam machinery uses precision metering pumps and digital controls to ensure the correct chemical flow. Regular calibration of pumps and verification of chemical densities prevent inconsistencies that could compromise foam quality. Operators should routinely check and record chemical ratios to maintain traceability and adjust parameters as needed.

Mixing Quality

Proper mixing of chemicals is essential for uniform foam structure. PU foam machinery is equipped with high-pressure or low-pressure mixing heads depending on the foam type. Key quality control practices include:

-

Inspection of Mixing Heads: Ensure that no residues or blockages affect the blending process.

-

Trial Runs: Conduct sample runs to verify proper chemical dispersion and reaction rates.

-

Monitoring Temperature and Pressure: Maintaining optimal conditions ensures the reaction proceeds uniformly, producing consistent cell structure and density.

Machine Calibration and Maintenance

Quality control also involves routine inspection and maintenance of the machinery itself. Regular maintenance ensures that all components, including pumps, hoses, valves, and sensors, operate accurately. Calibration of instrumentation and metering systems is essential to maintain chemical accuracy and foam consistency. Scheduled preventive maintenance reduces the likelihood of unexpected breakdowns that could disrupt production and compromise product quality.

Foam Testing and Inspection

Post-production testing is a critical part of quality control. Manufacturers assess foam characteristics to ensure they meet design specifications. Common tests include:

-

Density Measurement: Ensures uniform foam weight per unit volume.

-

Compression and Resilience Tests: Evaluates elasticity and durability.

-

Cell Structure Analysis: Detects air pockets or irregularities that may affect foam performance.

-

Surface Quality Checks: Identifies defects such as blistering, uneven expansion, or rough surfaces.

By regularly sampling and testing foam, operators can make real-time adjustments to machinery settings to correct deviations.

Automation and Digital Monitoring

Modern PU foam machinery incorporates digital monitoring and automation to enhance quality control. Sensors track chemical flow rates, temperature, pressure, and curing conditions in real-time. Data analytics and feedback loops allow the system to make automatic adjustments, reducing variability and improving product consistency. Remote monitoring and predictive maintenance features also help identify potential issues before they affect production quality.

Documentation and Traceability

Maintaining detailed records of machine settings, chemical batches, maintenance activities, and production parameters is a crucial component of quality control. Documentation ensures traceability, supports regulatory compliance, and enables manufacturers to analyze production data for process improvements. Proper record-keeping also helps identify the root causes of any quality deviations, allowing for corrective actions.

Benefits of Quality Control

Implementing robust quality control in PU foam machinery operations offers several benefits:

-

Consistent product quality and improved customer satisfaction.

-

Reduced material waste and production costs.

-

Lower risk of equipment failure and operational downtime.

-

Compliance with safety and industry regulations.

-

Enhanced efficiency and long-term reliability of machinery.

Conclusion

Quality control in PU foam machinery operations is critical for producing consistent, high-quality foam products while maintaining safe and efficient production. Monitoring chemical ratios, mixing quality, machine calibration, foam testing, and digital automation ensures that each batch meets specifications. Combined with proper documentation and preventive maintenance, these practices minimize errors, reduce waste, and enhance overall production performance. Manufacturers that prioritize quality control can achieve reliable operations, superior foam products, and a competitive advantage in the polyurethane foam industry.

Post Comment